"Some images on this page are computer-generated representations of the product and may differ from the actual product. Colors, textures, and other details may not be accurately represented in the images. Please refer to the product description and specifications for more information."

I purchased the Chopstick Master Gen.1 and have been very impressed with both the design and performance. The machining and build quality are exactly what I would expect from Bridge City, solid, precise, and thoughtfully engineered.

Setup was straightforward and once dialed in, the jig produces extremely consistent results. It saves a tremendous amount of time compared to shaping by hand, and the repeatability is fantastic for small batch production. The reference surfaces are true, adjustments hold firmly, and the overall workflow feels well planned.

As someone making chopsticks from a variety of hardwoods, including dense exotic species, the tool handles them without issue and keeps everything aligned cleanly through each pass.

Highly recommended for anyone serious about producing high quality, uniform chopsticks. Bridge City continues to deliver premium tools that justify their reputation.

This is the most well-built, over-engineered chopstick maker one could ever ask for.

- The kit is packed like nothing I have ever bought before, the boxing alone is a masterpiece.

- The quality and finish of the hardware is second to none.

- The engineering and thought that went into the design, make the results repeatable and amazingly consistent (even if you are not a master woodworker)

If you have read this far, you should buy it. You will not be disappointed.

After trying out the Chopsticks Master at the Catskill Mountain Maker Camp, I knew I had to have one! Extremely easy to set up and use.

Bought this on a whim to see if my kids would get involved with me on doing some projects. They have had fun making their own chopsticks and now want to start making them from my cutting board scraps.

I have been using the Chopstick Master v1 for a few weeks now, and I couldn’t be happier with it. It’s amazingly easy to use. The quality and construction is great. Precision is spot on. It makes perfect chopsticks every time! I would suggest to anyone purchasing it to get the 50 degree plane blade. It is essential when using figured or difficult grain woods.

Works fantastic and is a quality item that should last for years

High quality as expected. Blanks are hard to find 7mm 5/16 square in good hardwood. I now make my own from 3/8 square

CUSTOMER TESTIMONIALS

@wolfdogwoodworking

First set of chopsticks on their way!

@radeksworkshop

It's the time of the year when Elves and Woodworkers are very busy. I was too of course and now I can reveal this little gift - 3 pairs of chopsticks made with a help of @bridge_city_tool_works beautiful jig

@dogwoodcustombuilds

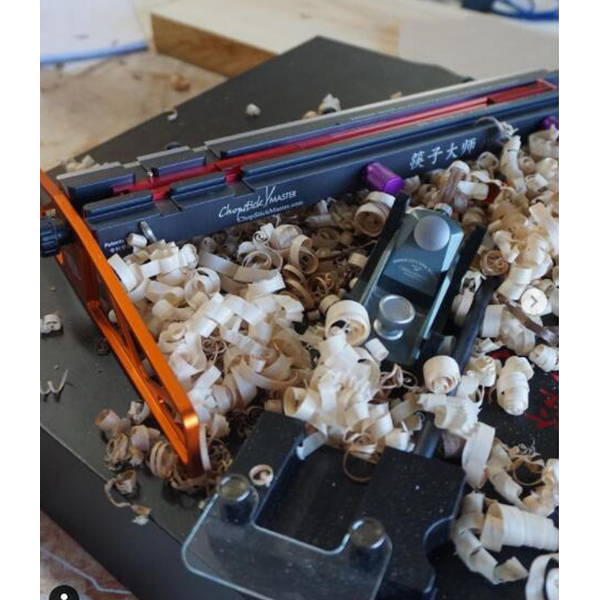

Spent some time this weekend testing out the Chopsticker Master from @bridgecitytoolworks !

-

I made 4 sets of chopsticks and a ton of fine wood shavings already! I’m going to sharpen the plane today and get back after it!

-

I’ll film some videos of the process this week!

@morineddie

Hank is now the chopstick master.

@radeksworkshop

I wanna do more woodworking unplugged so I got myself this beautiful set from @bridge_city_tool_works for making chopsticks. It comes with blanks, a pencil and even a little bottle for mineral oil. There's a mini block plane and a honing guide for sharpening the blade. You will also find a saw blade for cutting blanks. You can make thicker (Chinese) and thinner (Japanese) chopsticks with it. I am also gonna make additional arm that I will be able to use for making kumiko stock. Just a small piece of hardwood with a hole drilled in it will do.